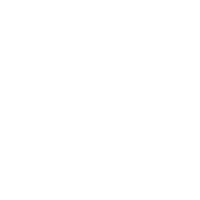

EineDoppel geflochtenes Polyester-Hafen mit UHMWPE-Bedeckungist ein hochwertiges, leistungsfähiges synthetisches Seil, das die immense Festigkeit eines Hightech-Kerns mit der überlegenen Haltbarkeit und Handhabung einer traditionellen Oberjacke verbindet.Es ist der Höhepunkt des Seilentwurfs., wobei die besten Eigenschaften zweier verschiedener Materialien genutzt werden, um ein Produkt zu schaffen, das größer ist als die Summe seiner Teile.

Dieses Seil ist die Wahl für kritische Anwendungen, bei denen ein Ausfall keine Option ist. Es umfasst Branchen von professionellen Schiffen bis hin zu schweren Industrie- und Rettungsoperationen.

Der Name wird aufgeschlüsselt

Der Name selbst ist eine perfekte Beschreibung seiner Konstruktion:

1. UHMWPE-Kern (Der Muskel):

UHMWPE steht für Ultra-High Molecular Weight Polyethylen.

Funktion: Dieser innere Kern trägt die große Mehrheit (typischerweise 85-95%) der Last.

Schlüsselmerkmale:

Außergewöhnliches Verhältnis von Stärke zu Gewicht: Es ist die stärkste künstliche Faser pro Gewichtseinheit, die im Handel erhältlich ist.Es ist deutlich stärker als Stahldraht desselben Durchmessers und schwimmt auf dem Wasser..

Sehr geringe Dehnung: Es hat eine extrem geringe Kriechfähigkeit und Dehnung unter Last, was eine präzise Steuerung ermöglicht.

Ausgezeichnete Chemikalien- und Abrasionsbeständigkeit: Sehr widerstandsfähig gegen viele Chemikalien, Öle und Lösungsmittel.

2. Polyesterdeckel (Die Rüstung):

Funktion: Diese äußere Hülle dient nicht in erster Linie der Festigkeit, sondern dem Schutz des Kerns und der Benutzerfreundlichkeit.

Schlüsselmerkmale:

Überlegene Abrasionsbeständigkeit: Es wirkt als Opferschicht gegen Verschleiß durch Winden, Schläger, Felsen und raue Oberflächen.kann durch die Einbettung von Kies in die Fasern oder durch scharfe, lokale Reibung.

Ausgezeichnete UV-Widerstandsfähigkeit: Polyester hat vielleicht die beste UV-Widerstandsfähigkeit aller gängigen synthetischen Fasern und verlängert die Lebensdauer des Seils in sonnigen Außenumgebungen drastisch.

Verbessertes Greifen und Handhabung: Polyester sorgt für ein viel sichereres Gefühl in der Hand, ist leichter zu knoten und greift besser an Schrauben und Winden als das berüchtigt glatte und rutschige nackte UHMWPE.

Farbe und Sichtbarkeit: Für Sicherheit und Identifizierung kann das Deckel leicht in helle, gut sichtbare Farben gefärbt werden.

3. Doppelgeflechtete Konstruktion (Architektur):

Dies ist eine spezifische Herstellungsmethode, bei der ein geflochtener Kern nahtlos und fest mit einer geflochtenen Abdeckung überzogen wird.flexibelDie Abdeckung ist ein integraler Bestandteil der Struktur, nicht nur ein lockerer Ärmel.

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!  Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!